A story of how some hand made puzzles were carefully ‘restored’ with the help of some friends.

Image from auction

A recent auction had a very interesting lot, it was for four puzzles which were listed as being Steel Engineer Made. How could I resist, especially as one was a kumiki cube. All four were well known puzzles, and I seemed to remember they were all in one of Edwin M. Wyatt’s books. When I checked I found that they were indeed listed in “Puzzles in Wood”.

They were;

The Double (?) Dovetail

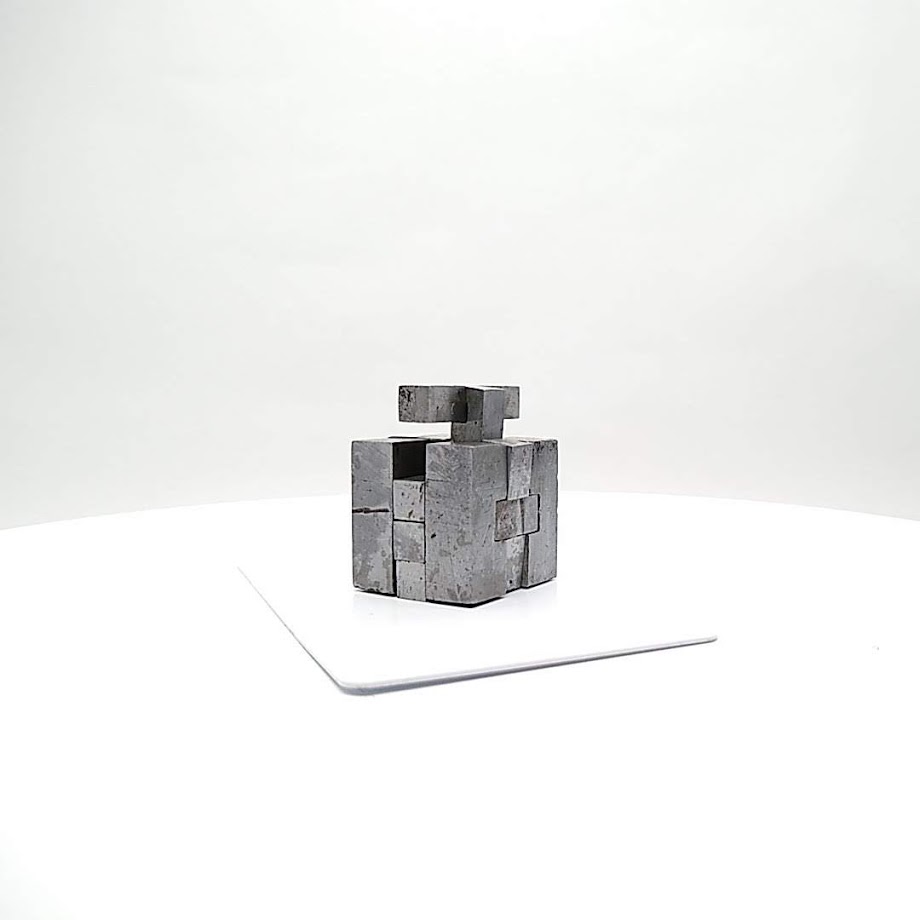

Built Up Cube

The “Impossible” Dovetail joint

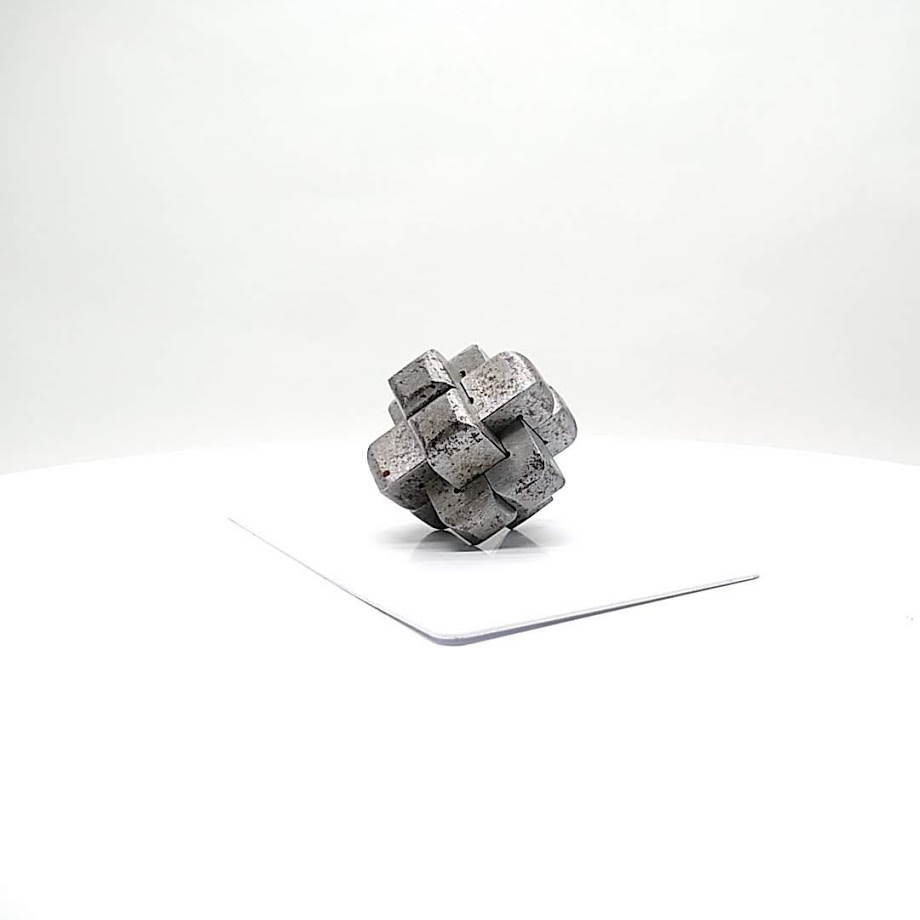

Six Piece Burr

So I decided to put a bid in, the estimate looked very attractive, so I registered and place my bid., Then I set a reminder for the day of the auction to watch it online. Everything was in place!

So the day of the auction and I had some meetings which went well, so I had a bit of free time. Logging on to the site I could see the auctioneer and watch as he sold the items before the puzzles. When the tiem for the puzzles came - someone else was bidding! A brief bidding war ensued, but I was victorious and very pleased with the win.

This was a week before the next MPP, so I confirmed my details and arranged for shipping, asking that they arrive before the next weekend. All went to plan and they arrived. I was a little surprised (as no dimensions had been supplied), at the size of the puzzles. The cube is approx 2.4cm (1 inch) along a side. But it is solid steel so the cube weighs in at 120gm (4.2 oz)

I only had chance to play with them briefly before I had to pack them to take to MPP, but I could not get any movement on any of them. I assumed that corrosion had set in and locked them up, so had mentally prepared myself for some chemical shenanigans to loosen them up. I should not have worried - the brains that go to MPP were soon on the task!

So I arrived with the 4 puzzles, wrapped in tissue paper to protect them (I know they are steel but that is how they arrived). Telling the story of how I got them, I handed them out for people to play with.

Speculation on who had made them, as the method shown on some of the pieces were identified as a Tool Makers technique, and if someone had cleaned them up before the sale. There is some pitting of the surface and lots of gunk in the six piece burr, but most of the surfaces appear to have been cleaned with something fairly abrasive.

Whilst we are examining them, the muscles of Allard are exercised on the Double Dovetail (that’s the T shaped one) and some movement is found. This encourages other to try and Chris soon has quite a lot of movement on the Impossible Dovetail. Sliding it back and forth soon exposes some yellowy substance, a little bit powdery but which can be scraped off with a fingernail. This is coming from inside the joint.

We decide this must be dried grease, which is basically gluing the pieces together. Lots of suggestions on how I can clean this out, with de-greaser, maybe some heat and a couple of other suggestions.

Unfortunately the hall doesn’t have a workshop, so we continue discussing how to clean them as we head to make a cup of coffee.

Now it must have been the spirit of McGyver or something, but seeing a water boiler and a bottle of washing up liquid we quickly began to think we may have a solution on hand to our problem.

I was a little nervous, as I had heard that water and steel do not always go well together. But I thought it was worth a try - and I could always clean any rust that formed later.

So a mug was taken, the Double Dovetail put in it, and boiling water added. Now how long should we wait? 20 seconds long enough? We were in uncharted territory, so the mug was tipped into the sink, so we didn’t scald ourselves (ok we tried to get it out with a teaspoon but that was too much of a dexterity puzzle for us). Picking up the puzzle and gently pulling it apart, and hey presto it worked. Then I remembered a lesson from school - Metal is a very good conductor of heat, and as this is a fairly solid piece of steel, it retains a certain amount of heat for some time. That is when the puzzle was dropped (not for the last time) with an exclamation that would get this blog blocked from most web filtering.

But the pieces were apart.

Obviously the pieces needed to be picked up with something, so kitchen towels were used to insulate us from the heat (to a lesser degree than we first thought), and accompanied by various exclamations, the sound of steel hitting the worktop, the pieces were gradually cleaned.

Now at this point I must give full credit to Chris - he undertook this task with some gusto, and seemed to have come prepared for this exact task, pulling out a ‘brass pen’ - another learning experience as I didn’t know they existed, to clean the gunk from inside the puzzle.

Now the “Impossible” Dovetail came apart quite easily, as did the six piece burr, but as puzzles they are fairly easy to spot which how they work. These were cleaned up - using the heat, swear, drop, clean method - and worked well. The craftsmanship was such that the edges of the metals were sharp and the movement smooth.

But the cube was proving very difficult. The process was;

Place in boiling water.

Remove and try not to burn yourself

Push on the possible key pieces, whilst juggling it to stop it scalding your hands

Find it had cooled too much anyway, so wasn’t going to come apart.

return to step 1.

Cube piece after being taken apart.

This went on for a while, and I was beginning to think a soak in WD40 was going to be needed, but Chris encouraged me by saying that it would be a bit of a failure if we didn’t get all 4 puzzles apart and cleaned up. Eventually using a metal rod resting on the worktop, and pushing the cube down, the key piece was found and the puzzle was taken apart. You can see below the amount of dirt inside some of the pieces which were holding the puzzle together.

partly cleaned

So we had success, 4 puzzles that worked and just needed a final bit of cleaning up when I got home. The dovetails work perhaps a little too well, as there is little/ no friction to keep them together.

The cube looks like it has been hand cut, which differs from the others, which all seem to have some machining on them.

Some picture below of how they look, now they have been cleaned and coated in a light coating of Renaissance wax.

So I now have 4 steel puzzles in my collection. I have asked if the auction house could pass my details to the seller, as I would love to know more about the person who made them. But for now, it is the memories of another great MPP, with perhaps a little more swearing than usual, that these puzzles bring.